Model:

Your Model No.:

Mfr. Model No.:

One ladder is rarely suitable for all jobs. The first "STEP" in ladder safety is selecting the correct ladder for the task at hand by answering the following questions:

Straight and extension ladders require support at both top and bottom. They are very versatile and available in a variety of sizes ranging from 16 to 60 feet in length.

Select the correct SIZE Extension Ladder for your needs.

Step ladders are designed to be self-supporting, and come in a variety of styles, and sizes ranging from 2 to 16 feet in length, and are in most cases designed to be used by one person at a time.

Trestle and 2-way step ladders can be climbed from either side, or support one person on each side.

Platform step ladders provide a large standing area which is more comfortable and safer to work from at fixed heights.

Choose the correct SIZE step ladder for your needs.

Combination ladders are very versatile, and can often be configured in several different positions, each best suited to a particular task. Most models can be used as a straight, 2-way step, scaffold, or stairway ladder. Their compact nature allows for easy storage and transport. They are available in several sizes and styles including telescopic, articulating and multi-way.

| Step Size | Max. Standing Ht. | Approx. Max. Work Ht.* |

| 4' | 1'11" | 8' |

| 5' | 2'10" | 9' |

| 6' | 3'9" | 10' |

| 7' | 4'9" | 11' |

| 8' | 5'8" | 12' |

| 10' | 7'7" | 14' |

| 12' | 9'6" | 16' |

| 14' | 11'5" | 18' |

| 16' | 13'4" | 20'** |

| Ext. Size | Max. Standing Ht. | Approx. Max. Work Ht.* |

| 16' | 12'6" | 9'6" |

| 20' | 16'6" | 13'6" |

| 24' | 20' | 17' |

| 28' | 24' | 21' |

| 32' | 28' | 24' |

| 36' | 31' | 28' |

| 40' | 33'6" | 30'6" |

| 44' | 37'6" | 34'6" |

| 48' | 41' | 38'6" |

| 60'*** | 46'6" | 43'6" |

*Assumes 5'6" person with 6'6" reach **Consider scaffolding *** Three section ladder

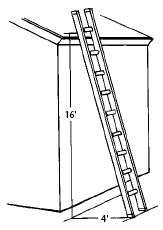

The feet of a straight or extension ladder should be set at a point one foot horizontally outward from the upper support, for every four feet of vertical distance between the ladder feet and the upper support point.

Please note that each Featherlite extension, straight, and combination ladder is equipped with a label similar to this, to assist in set-up. With the ladder set up correctly (approx. 76° from horizontal), the long leg of the “L” will appear vertical.

The most common material of construction.

An "engineered" material consisting of continuous strands of high-strength glass fibres and mats encapsulated in a resin matrix.

A natural material, most popular prior to introduction of aluminum and fibreglass ladders.

| Max. Load Capacity | Rated Use | CSA | ANSI |

| 200 lbs. | Light-Duty Household Designed for infrequent household chores, cleaning, painting, etc. |

Grade 3 | Type III |

| 225 lbs. | Medium-Duty Commercial Designed for moderate use by homeowners, painters, handymen, etc. |

Grade 2 | Type II |

| 250 lbs. | Heavy-Duty Industrial Designed for use by contractors in maintenance, construction and industrial applications |

Grade 1 | Type I |

| 300 lbs. | Extra Heavy-Duty Designed for frequent use in maintenance, construction and industrial applications |

Grade 1 | Type 1A |

| 375 lbs. | Special Heavy-Duty Designed for the most demanding industrial and construction applications |

Grade 1 | Type 1AA |

While CSA recognizes neither the Type 1A or 1AA duty ratings, many products have been designed and tested to meet or exceed the higher ANSI Type 1A and 1AA load ratings commonly specified by industrial and trades users, in addition to retaining CSA Grade 1 certification.

In most users' minds, handling and using ladders is straightforward and carefree. Unfortunately, some 4000 people are hospitalized annually in Canada as a result of ladder incidents. Incident statistics show that users regularly fail to recognize and eliminate or manage potential hazards. Incidents involving ladders often result in serious injury and may result in permanent disability or death.

Once a ladder appropriate for the task has been selected, MUST be thoroughly inspected (see section 3) before set up and use!

For Straight and extension ladders the correct set-up angle from horizontal is approx. 76 degrees (from whence comes the 1:4 rule); however, 5 degrees either way of 76 degrees is generally OK. At 76 degrees, the anti-slip feet of the ladder provide the maximum resistance to sudden outward “kick-out” of the ladder feet. Angles steeper than 80-degrees expose the user to falling over backwards; while, at angles shallower than 70 degrees, “kick-out” force intensifies perilously. Ladders “kick-out” when the slip-resistance provided by the ladder feet, is exceeded by an opposing force that intensifies as a user ascends a ladder.

Opposing slip-resistance is a frictional force dependent upon the combined weight of ladder and user; type and condition of the rubber foot-pads and type and condition of the surface underfoot. If the user climbs higher than available friction allows, the ladder feet suddenly and irreversibly, accelerate outward under the force of gravity.

In the following diagrams, red arrows indicate the direction and magnitude of the “kick-out” force that develops at different set-up angles, as a 200-lb climber approaches roof level. Assuming an average slip-resistance of 100 lb-f (see green arrows), note that the 100% margin of safety at 76 degrees, reduces to 33% at 72 degrees, and to 0% at 64 degrees. At that point a “kick-out” incident is highly probable under all but perfect footing conditions!

To avoid “kick-out”, watch your set-up angle, ensure a clean, slip-free footing, and if in doubt, use your “picks”, or block the feet from moving.

| Ladder Size | Overlap Required |

| Up to and including 32' | 3' |

| Over 32', up to and including 36' | 4' |

| Over 36', up to and including 48' | 5' |

| Over 48' | 6' |

Once you have selected the correct ladder for the job, it should be carefully inspected before each set-up and use. NEVER USE A DAMAGED LADDER. Many incidents are caused by the use of damaged or otherwise unsafe ladders, and result in severe injury or death.

Please refer to the inspection procedure and form for a full outline of what to look for when inspecting your ladder(s). This outline includes the following key warning signs:

Fibreglass ladders are non-conductive, strong and durable. Fibreglass rails are manufactured in a process called pultrusion, wherein continuous strands and mats of glass are encapsulated in thermoset resin and molded into a variety of rail profiles. The resin incorporates colour pigments and UV inhibitors. The UV inhibitors protect the resin from surface UV and atmospheric corrosion. On average every 3-5 years, depending on exposure of the ladder to direct sun, and atmospheric pollutants, the surface of the fibreglass should be checked for “fibre prominence” as may be witnessed by a rough feel when you run your hand across it. If prominence is noted, the ladder rails should be lightly “sanded” using a nonabrasive ScotchBrite® scouring pad, solvent-cleaned then “painted” with a brush-applied, transparent, 2-part polyurethane coating. (i.e. Sherwin-Williams #RS 6010 clear enamel with #RS 9820 hardener). This coating will provide further UV, and atmospheric corrosion protection, and should last for at least another 3-5 years.

Despite their strength and durability, fibreglass ladders can be broken, cracked, gouged or punctured if not protected from damage, or used improperly. Fibreglass ladders should be carefully inspected, before each use, for the following defects:

A see-through separation of the fibreglass laminations visible from both sides. The ladder should be removed from service until the rail can be replaced or the ladder disposed of.

A separation of material, not visible from the other side. The ladder should be regularly and carefully inspected to ensure it does not deteriorate further. If moisture is allowed to penetrate the rail, the non-conductive properties are greatly reduced.

To reduce the risk of water penetration, clean the area with a mild solvent solution, and apply a polyurethane clear-coat.

A surface crack that does not penetrate the laminate layer. Inspect regularly to ensure it has not expanded, especially into the laminate area. If moisture is allowed to penetrate, the non-conductive properties of the rail are greatly reduced. A polyurethane clear-coat or an exterior quality paste wax may be applied to inhibit moisture penetration.

A puncture that is visible from both sides. The ladder should be removed from service until the rail can be replaced or the ladder disposed of.

Like any equipment, your ladder requires periodic preventive maintenance.

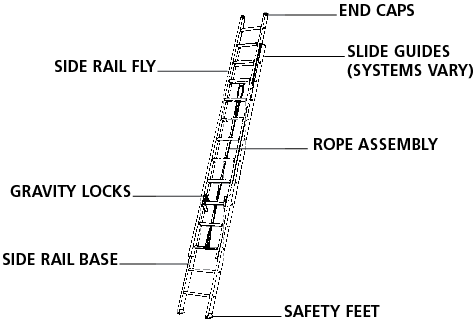

The entire ladder should be cleaned on a regular basis and moving parts should be kept clean and lightly lubricated. Slide guides and safety feet should be replaced if worn and the rope assembly replaced at least once a year. In order to maintain the maximum dielectric properties of fibreglass ladders, they should be regularly cleaned with mild detergent and water and waxed with an exterior quality paste wax. The wax helps to keep water and dirt out of scratches and gouges that might otherwise reduce surface dielectric properties.

There are only a few ladder components that can be repaired in the field. It is very important that replacement parts are properly installed on your ladder. An incorrectly installed part is as dangerous as a broken or worn out one. In most cases parts can be replaced with the self-locking nuts, bolts and washers; however, in some instances riveting is required.

If in doubt, check with a TENAQUIP Ladder Specialist.

| Extension Ladder |

| Safety Feet |

| Rope Assembly |

| Rung Locks |

| Slide Guides |

| Protective End Caps |

| Cog Wheels |

| Pail Tray |

| Step Ladder |

| Safety Feet |

| Spreader Arms |

| Head Tray |

| Pail Tray |

The simple rule “if in doubt tag it out” applies when a ladder has been damaged badly enough to break, bend, or twist parts. Tag it out-of-service until it can be repaired by a competent technician, or disposed of.

It is important to the success of your program to assign responsibility, give authority and hold someone accountable for the program. This person should typically be someone in a supervisory, maintenance, or health and safety related role in the workplace.

In order to do this you will need to take an inventory of your ladders and give each a permanent identification number. Determine the frequency of use of each ladder and with this information, set up the appropriate inspection frequency for each ladder.

A thorough inspection of each ladder should be carried out. Those that require repair or replacement should be immediately tagged DO NOT USE. These items should be logged in the control manual indicating: the nature of the problem; the individual responsible for corrective action and the due date for repair or replacement.

Upon completion of repair, the control manual log entry should be signed by the person responsible for the repair, and the supervisor accepting the ladder ready for use (a maintenance work order system works well in this situation).

A formal ladder control program still requires the user to complete an inspection before each first use of the ladder. See the Ladder Inspection Form.

Max quantity is 999999999. Your cart item has been updated

Model:

Your Model No.:

Mfr. Model No.:

Qty.: