Model:

Your Model No.:

Mfr. Model No.:

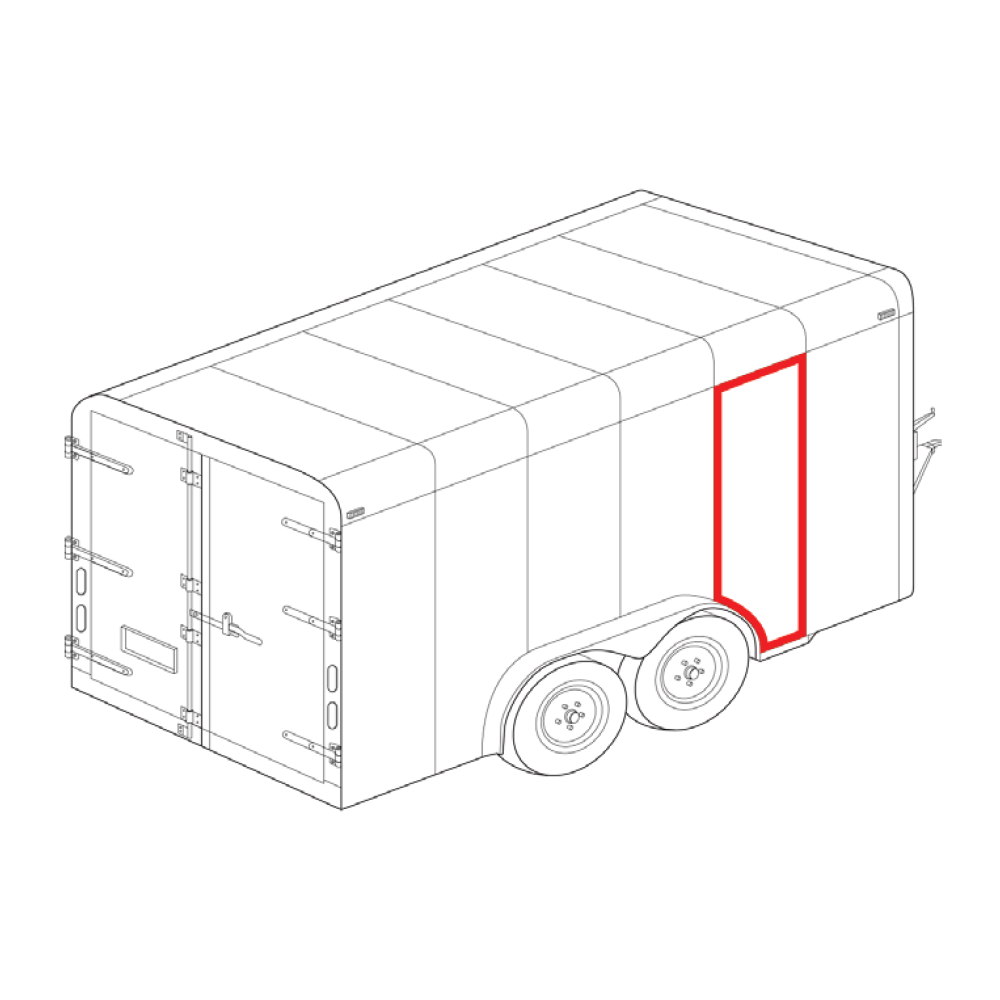

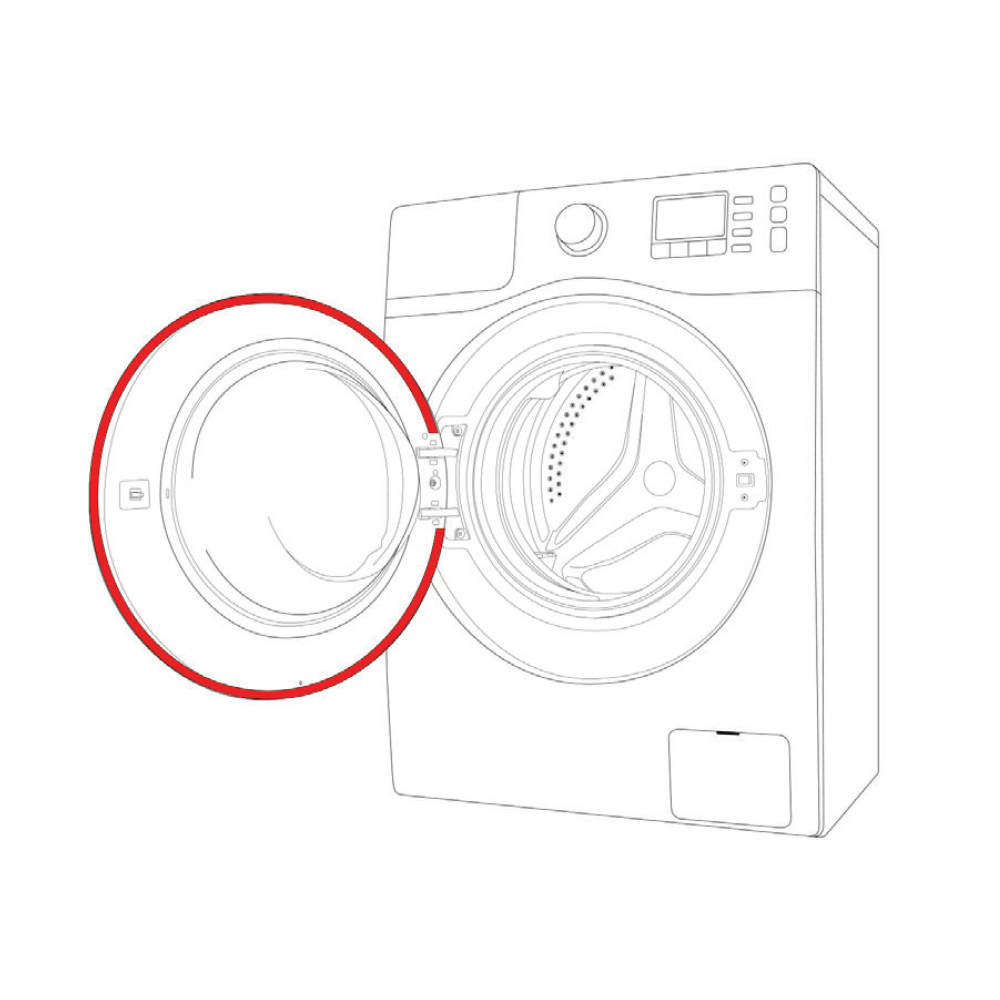

Bonding solutions that fit any shape.

Enhance your design appearance with virtually invisible bonding. Don't be distracted by rivets, welds, or screws. With these tapes, you can use new and innovative materials to improve the look of your products while optimizing performance, preventing bi‑metallic corrosion, and streamlining your production processes.

With a bond built to withstand the severities of exposure, 3M™ VHB™ Tapes resist extreme heat, extreme cold and cycling temperatures, UV rays, moisture, and solvents. They seal against environmental conditions and damp vibration to reduce metallic wear and tear.

For your most demanding bonding applications, 3M™ VHB™ Tapes distribute dynamic or static stress over the entire surface, improving holding strength and eliminating the need for mechanical fasteners.

These tapes are simple and easy to apply, saving you time and money. The tapes bond on contact, assemble easily, and can be cut to precise shapes and sizes for custom applications. VHB™ Tapes don’t require a cure time and can be used in pre‑assembly processes.

Selecting the right 3M™ VHB™ Tape for your application.

When you’re reviewing options, consider the following factors:

| Temperature Resistance | |||||||

|---|---|---|---|---|---|---|---|

| Mfr. Prod. No. | Tenaquip Model No. | Tape Thickness without Liner | Liner Type | Description | Adhesive Type | Minutes and Hours | Days and Weeks |

| 4941 Tape Family | |||||||

| 4926 | AMA341, AMA339 | 15 mils (0.4 mm) | A | Gray, closed-cell acrylic foam tape. Excellent combination of strength, conformability, and adhesion to high and medium surface energy materials. Plasticizer resistant. UL 746. | Multi-purpose Acrylic | 300°F (150°C) | 200°F (93°C) |

| 4936 | AMA354, AMA355, AMA353 | 25 mils (0.6 mm) | A | ||||

| 4936F | AMB502 | 25 mils (0.6 mm) | F | ||||

| 4941 | AMA358, AMA359, AMA153, AMA360, AMA152, AMA357 | 45 mils (1.1 mm) | A | ||||

| 4941F | AMA362, AMA361 | 45 mils (1.1 mm) | D | ||||

| 4956 | AMA391, AMA392, AMA390 | 62 mils (1.6 mm) | A | ||||

| 4956F | AMA393 | 62 mils (1.6 mm) | F | ||||

| 4991 | AMA171, AMA172, AMA170 | 90 mils (2.3 mm) | F | 250°F (121°C) | 200°F (93°C) | ||

| 4919F | AMA141 | 25 mils (0.6 mm) | F | Black version of 4936F. | 300°F (150°C) | 200°F (93°C) | |

| 4947F | AMA161 | 45 mils (1.1 mm) | F | Black version of 4941F. | |||

| 4979F | AMA400, AMA401, AMA399 | 62 mils (1.6 mm) | F | Black version of 4956F. | |||

| 5952 Tape Family | |||||||

| 5925 | AMA404, AMA403 | 25 mils (0.6 mm) | F | Black or white, closed-cell acrylic foam tape. Good adhesion to many painted surfaces, including powder coated paint. UL 746C. | Modified Acrylic | 300°F (150°C) | 250°F (121°C) |

| 5952 | AMA405, AMA181, AMA180 | 45 mils (1.1 mm) | F | ||||

| 5962 | AMA182, AMA183 | 62 mils (1.6 mm) | F | ||||

| GPH Tape Family | |||||||

| GPH-110GF | AH140 | 45 mils (1.1 mm) | F | Gray, closed-cell, conformable acrylic foam. Superior high-temperature performance for powder coat or liquid paint processes and multi material bonding. | Modified Acrylic | 450°F (230°C) | 300°F (150°C) |

| LSE Tape Family | |||||||

| LSE-060WF | AG867, AG868, AG869, AG866 | 25 mils (0.6 mm) | F | Developed specifically for LSE substrates such as polypropylene (PP), thermoplastic elastomers (TPE), and thermoplastic olefins (TPO). | LSE Acrylic | 300°F (150°C) | 200°F (93°C) |

| LSE-110WF | AG871, AG872, AG873, AG870 | 45 mils (1.1 mm) | F | ||||

| LSE-160WF | AG875, AG876, AG877, AG874 | 62 mils (1.6 mm) | F | ||||

| 4950 Tape Family | |||||||

| 4920 | AMA332 | 15 mils (0.4 mm) | A | Closed-cell acrylic foam tape. UL 746C. | General-purpose Acrylic | 300°F (150°C) | 200°F (93°C) |

| 4929 | AMA343, AMA345, AMA342 | 25 mils (0.6 mm) | C | ||||

| 4930 | AMA348, AMA349, AMA347 | 25 mils (0.6 mm) | A | ||||

| 4949 | AMA374, AMA375, AMA376, AMA377, AMA373, AMA163 | 45 mils (1.1 mm) | C | ||||

| 4950 | AMA166, AMA379, AMA164, AMA378 | 45 mils (1.1 mm) | A | ||||

| 4955 | AMA388, AMA387 | 80 mils (2.0 mm) | C | ||||

| 4959 | AMA397, AMA398, AMA396 | 120 mils (3.0 mm) | C | 400°F (204°C) |

300°F (150°C) | ||

| 4910 Tape Family | |||||||

| 4905 | AMA140, AMA322, AMA323, AMA321, AMA320 | 20 mils (0.5 mm) | F | Clear, acrylic construction for joining transparent material. | General-purpose Acrylic | 300°F (150°C) | 200°F (93°C) |

| 4910 | AMA329, AMA327, AMA328, AMA330, AMA331, AMA326 | 40 mils (1.0 mm) | F | ||||

| Other VHB™ Tapes | |||||||

| 4611 | PC456, PC455, PC454 | 45 mils (1.1 mm) | |||||

| 4646 | AMA134, AMA316 | 25 mils (0.6 mm) | |||||

| 4655 | AMA318, AMA317 | 62 mils (1.6 mm) | |||||

| 4932 | AMA351, AMA352, AMA350 | ||||||

| 4945 | AMA157, AMA367, AMA369, AMA158, AMA366 | 45 mils (1.1 mm) | |||||

| 4952 | AMA384, AMA168, AMA385, AMA383, AMA382 | ||||||

| CV62F | PF685, PF686 | 62 mils (1.6 mm) | |||||

| F9473 | AMA283, AMB094 | 10 mils (0.25 mm) | E | ||||

Max quantity is 999999999. Your cart item has been updated

Model:

Your Model No.:

Mfr. Model No.:

Qty.: